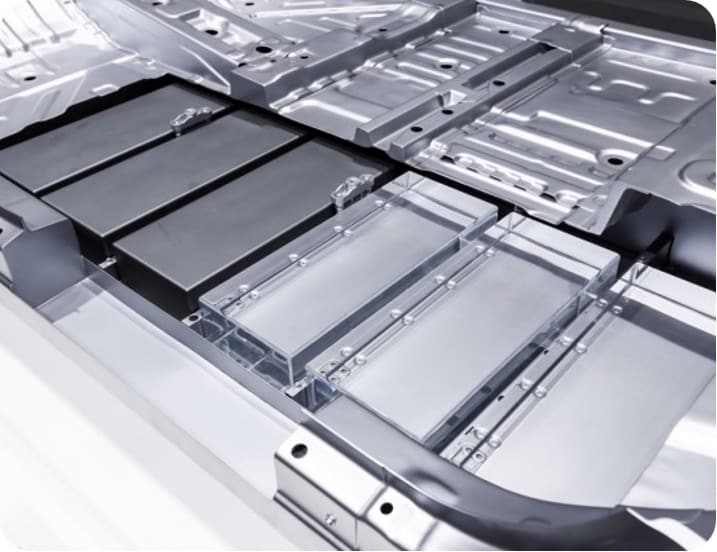

Automobile cold stamping dies refer to special process equipment used in cold stamping to shape metal or non-metal materials into automotive parts. Cold stamping is a pressure processing method that involves applying force to materials using molds mounted on a press at room temperature, causing separation or plastic deformation to obtain the desired part

Application scenarios and importance of automotive cold stamping dies .

Automobile cold stamping dies are widely used in the manufacturing of automobiles, producing various automotive components. The quality, production efficiency, and cost of stamped parts are closely related to the design and manufacture of the dies. The level of die design and manufacturing technology is one of the key indicators of a country’s product manufacturing capabilities, significantly determining the quality, efficiency, and ability to develop new products .

Classification and characteristics of automobile cold stamping dies

Automobile cold stamping dies can be classified according to their functions and structures, for example:

1. Single process mold: A mold that completes one process.

2. Composite die: a die that completes two or more stamping operations in one stroke of a press.

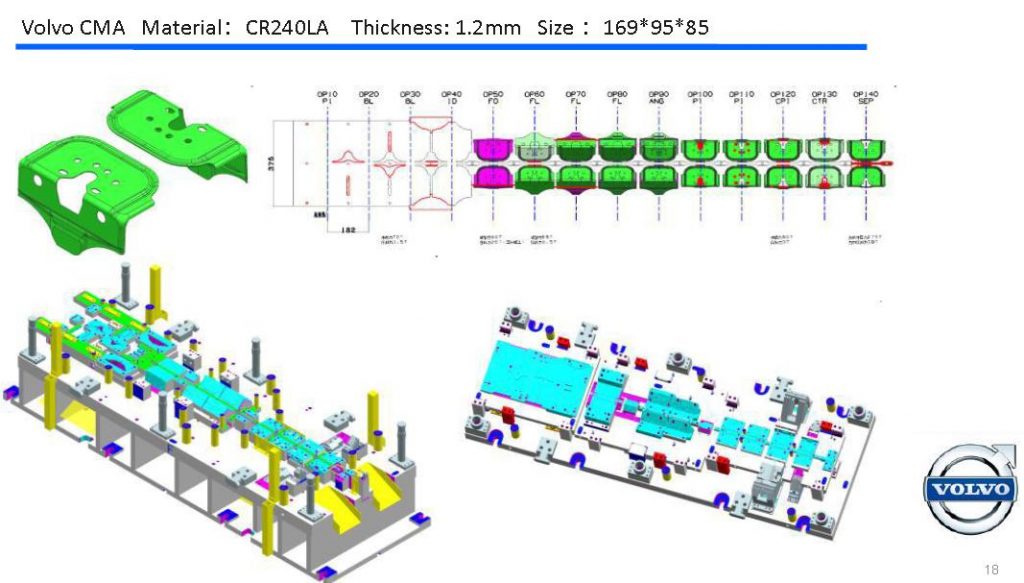

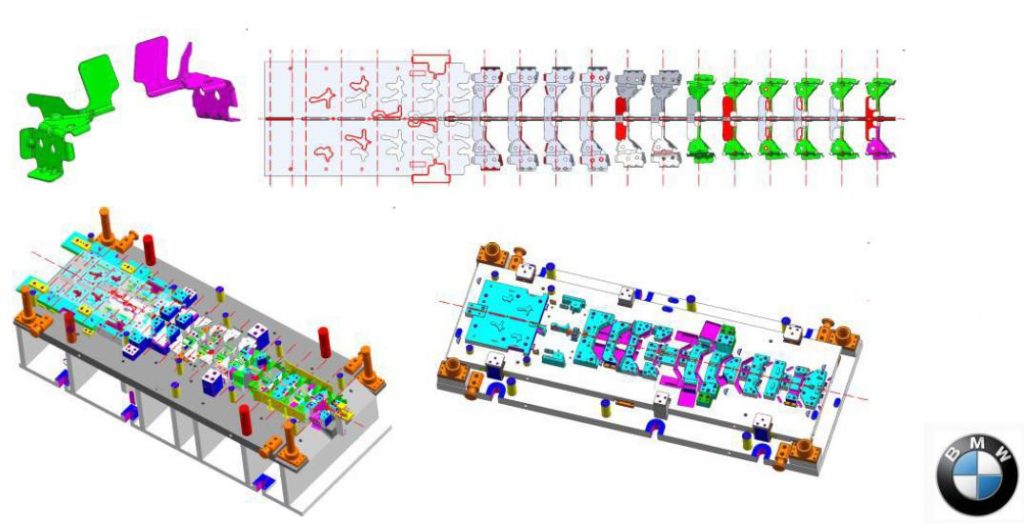

3. Progressive die (also known as continuous die): A mold that completes multiple stamping operations in a single stroke of the press through multiple stations.

The characteristics of these molds include:

- High precision: can produce high precision parts.

- High efficiency: suitable for mass production, improve production efficiency.

- Low cost: compared with other manufacturing methods, stamping costs are lower